The gussets in the drawing look a little small but the design works fine for something like the Rogue squat stand. Why would this rack require a cross member when the front posts are essentially a squat stand?

I do like the idea of a cross member as a built in deadlift jack and have thought of adding one to my rack with a small ramp to roll the bar up on to gain a 1/2" or so of lift.

|

|

Thread: New Open Power Rack Build

-

10-18-2014, 09:59 PM #61

-

10-18-2014, 10:25 PM #62Registered User

- Join Date: Aug 2012

- Location: Hamilton, Ontario, Canada

- Age: 47

- Posts: 2,097

- Rep Power: 5289

-

10-18-2014, 10:32 PM #63

-

10-18-2014, 10:34 PM #64

-

-

10-18-2014, 11:21 PM #65

I admit I am confused by the design. If there is room for a loaded bar to travel throughout the open space at the top why isn't there room for full height posts of a traditional rack? Are the four full height posts in the drawing welded at the top but bolted at the bottom? Why is there no bracing to prevent side to side sway?

From what I've read I don't see reason not to build a regular rack with fully welded sides that bolt together with braced cross members. It takes up essentially the same space and can be dissembled enough to transport.

-

10-18-2014, 11:25 PM #66Harmonia Early Music: http://www.harmoniaearlymusic.org

SymphonyCast: http://symphonycast.org

Performance Today: http://performancetoday.publicradio.org

Studio360: http://www.studio360.org

RadioLab: http://www.radiolab.org

TED Radio Hour: http://www.npr.org/programs/ted-radio-hour/

This American Life: http://www.thisamericanlife.org

On Being: http://www.onbeing.org

Snap Judgment: http://www.snapjudgment.org/radio-show

Radio IQ: http://wvtf.org

LibriVox: https://librivox.org/

-

10-19-2014, 12:00 AM #67

-

10-19-2014, 02:45 AM #68Registered User

- Join Date: Jul 2014

- Location: Cape Town, Western Cape, South Africa

- Posts: 59

- Rep Power: 241

I agree with Seatard.

The current design is weak as the front two posts ar not as sturdy as the rear four. This design concentates on the plate pins and storage. A bench press fail under heavy weight may cause the front two posts to bend or fail sideways.

I would rathe make it a four post that go to the top. The four posts must be connected with cross or side beams. It can be made to be bolted toether to make transport easier. The plate storage can be made and igured out on a second phase. And you will use less steel.

You have one chance to make your rack. Consider the advice of more experienced users. Once you have made it and you possibly are not happy, you have to change or adapt at cost and effort.

This is my half cents of opinion.

I made my own rack as well, but I first read what others on this forum said and why. Now I am happy with my choices made. I can ow see why and that some of my innitial choices were made on not informed information.

Steel is expensive.Regards

Johan

-

-

10-19-2014, 03:04 AM #69

-

10-19-2014, 06:55 AM #70

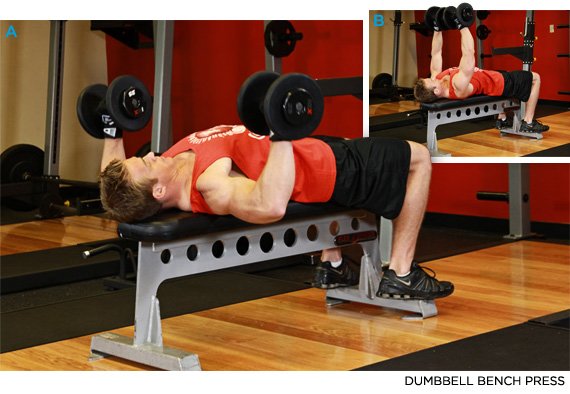

I don't really understand the attachment of the uprights in the picture. Instead, I'd use a Rogue-style attachment with 3/8" plate on both sides. I wouldn't worry about anything moving. It'll be just as strong as a weld, if not more so:

The important part, to make sure things aren't moving/flexing is to design the connecting member at the bottom and the pullup bar at the top correctly (read: beefy, with multiple bolt points, etc). You want them to be braced really well, etc. Again, if properly built, that front upright won't go anywhere. Even if you're lifting 1k lbs and drop it from as far as you can up, even if you can somehow build up angular velocity with straps, good luck having those uprights fail. You can further reduce the flex, by welding bolt-down feet to the bottom the way Legend Fitness does. It'll add more stability to the feet, for torsional rigidity of that tubing.

Don't get me wrong, they can move as all metal flexes, but you're talking millimeters over that distance and they won't break.

Again, that's based on the design that I have in my head. Don't know exactly how this will be implemented in your case.USAPL RAW Competitor

>500/>300/>600

▪[M]====[6]▪ Mech6 Crew #25 ▪[M]====[6]▪

[]---[] Ivanko Barbell Crew #100 []---[]

-

10-19-2014, 06:59 AM #71Registered User

- Join Date: Aug 2012

- Location: Hamilton, Ontario, Canada

- Age: 47

- Posts: 2,097

- Rep Power: 5289

You don't have space for this. Once you allow for plate clearance along the back wall, you will have about 2 feet left to get a bench in and out (and barely or not enough space to remove your safety pins to adjust them)Then have to step over or move the bench to get to each side of the rack for every plate you add or remove. I'm sure it can be done, but why?

The open top is pointless and less stable without adding a bunch of support. Even more pointless is a pull-up bar mounted to the top of a rack being designed for a lower height ceiling.

If it needs to be taken apart quickly, more welds, less bolts... not the other way around. Making it out of 80 small pieces does not speed up assembly/disassembly. Weld the sides and bolt on the crossmembers, drop the gussets.. It is additional cost in hardware and bracing that you don't need. If it needs to be in small pieces to get it in or out then stick to bolts/gussets.

I would also use a sumo base for more function and some additional flexibility to deal with uneven floors, but that's just a personal preference.

I see no reason not go with a traditional style rack in your space and then get creative with a plate storage solution (wall mounted pins?). The space will be far more useful and simple.

Half of this thread is filled with solutions to problems you don't need to have.

edit: just saw the full rack design. I'd still lose the plate storage because of space. I still don't think you have room to move the pins.Last edited by GarageIron; 10-19-2014 at 07:26 AM.

()---() York Barbell Club #30 ()---()

-

10-19-2014, 08:10 AM #72

You may be right that I'll not have space to move the pins. And I included the plate storage to make the thing bottom heavy. Otherwise I'll save a ton of money by losing the additional plate storage uprights. Also do you think the decrease in footprint, if I lose the storage, will hamper the stability of the system? Because remember I'll also do pull ups on this. The bolt gusset thing stays because this place is in an apartment. The doorways are about 6.5 feet by 3.5 feet. So, I'll have to have small pieces. I was wrong in saying fast disassembly. What I meant was more convenient to take apart and store. This thing is 49" wide and my floor is pretty even. So I'll skip the sumo. Gonna post a revised sketch soon.

Thanks.

-

-

10-19-2014, 08:13 AM #73

My sketch is not clear at this magnification but there are 5mm plates welded to the bottom of the uprights and there are 5 mm gussets like the ones in your picture on both sides. Moreover they are all 1" bolts. I hope this makes it clear. I just haven't drawn the bolt holes as this is something I'll explain to the fabricator in person. I need to make sure that the welded feet bolts don't foul with the gusset bolts.

-

10-19-2014, 11:40 AM #74

Guys how does this look. Red parts are gonna be welded. The base is gonna be welded. The red part is gonna be bolted to the base via welded 5mm plates at the bottom and gusset plates are for reinforcement. Depth of rack is 24" measured from inside to inside of the two uprights. Width is 49" in total and height is 90".

Thanks.

-

10-19-2014, 12:19 PM #75

-

10-19-2014, 12:22 PM #76

You are nearly there IMO.

Take a look at the elitefts 3x3 Oldschool power rack. It is built very close to what you have described as wanting. Or the first post or post #248 in this thread:

http://forum.bodybuilding.com/showth...8840393&page=9

The sides are completely welded and the cross pieces are bolted. If you are still planning to bolt down to plywood you don't need the lower cross piece in the back. If you don't want to bolt it down then add that piece like in your last drawing. I think power racks should be kept simple so keep that in mind if you read my post.

-

-

10-19-2014, 12:25 PM #77Registered User

- Join Date: Jul 2014

- Location: Cape Town, Western Cape, South Africa

- Posts: 59

- Rep Power: 241

Look at this forum page (page 62). My rack is the light green one.

I am very happy with it so far. I did my first two workoouts on it. Have to adjust one thing though, but I am happy overall:

http://forum.bodybuilding.com/showth...post1303227751

It took a while to build and some effort, but it is worth it. The ready available ones I have seen so far is not worth it here in SA and way too expensive.Regards

Johan

-

10-19-2014, 12:32 PM #78Registered User

- Join Date: Aug 2012

- Location: Hamilton, Ontario, Canada

- Age: 47

- Posts: 2,097

- Rep Power: 5289

Looks good, but I would consider losing the bolts on the upright and just stick to a gusset plates (similar to what Edge does and now Rogue as in the photo above. Otherwise your rack is sitting on the hardware on the floor (unless you are threading the bottom plate? In which case you risk cross threading/stripping at each assembly) the gussets will be more than enough. If you are worried about stabilty for pull ups you could move the pull-up bar closer to the center of the rack or use a fat/skinny type bar like a Rogue R3 for the top bracing and pull-ups.

Basically it looks like where you are headed with this is similar to the Rogue flat foot rack, just smaller and with some welds and a lower brace, which I would keep.

Last edited by GarageIron; 10-19-2014 at 12:44 PM.

()---() York Barbell Club #30 ()---()

-

10-19-2014, 02:42 PM #79

I agree about not welding the plate to the upright, just use the gusset side plate with four bolts like the pictures. It is very solid with that design on my rack, front to back there is no sway, side to side is minimal movement. If you need room for the rod/pipe safety, you might want to see if they can make strap safeties. They require about the same room to adjust as j-cups.

▪█─────█▪ Ivanko Barbell Crew #76 ▪█─────█▪

-

10-19-2014, 05:03 PM #80

Looks good, OP...you've come quite a ways since you started. I am curious, one of the reasons you wanted to have an open top or multi press rack was to OH press inside. With the full cage (which I would normally prefer as well), will you be able to do this? At 6'2" your bar will be going high, will you have the clearance inside under the cross members or have you decided to do this some other way (sitting presses or pressing on the front/outside)?

Just curious, I don't see much advantage to a multipress design, unless that was a goal and you said it was.▪█─────█▪ Equipment Crew #4 ▪█─────█▪

Ivanko Crew #9

York Barbell Crew #13

-

-

10-19-2014, 05:23 PM #81

What's quicker to dissamble - Sides that are 5 pieces with 12 bolts, 12 nuts, 24 washers; or a welded side with zero dissassembly? Yeah it's a bitch to move but how often do you move it?

I don't think a bolted side plate is the same as a gusset. Not by my definition at least. I was thinking of a triangular plate welded in the center of both tubes. I had the powertec rack which had tie plates exactly like your drawing. The slightest play in the bolt holes would allow the uprights to move a fraction of a degree. That fraction of a degree spanned over 8' can easily make for a 1/2" variance at the top. Basically what I'm saying is - it's a pain in the ass to get everything aligned perfectly plumb and level.

If you insist on having bolted uprights I would consider using attachment like the Powerlift rack. Same method as the Dynamic rack posted above. I have owned the Powertec (Rogue style attachement) and now the Powerlift, and with the Powerlift it's not susceptible to being put of plumb like the other designs.[]---[] Equipment Crew Member No. 21

-

10-19-2014, 06:37 PM #82

I think he said something about his doorway being small and he was not in a rush to unbolt it, but wanted it to have smaller parts when taken apart for storage. Welded uprights would be more solid than bolts but provide zero flexibility if his space ever changes. I can't use a welded design in my current setup because of a beam that goes between my crossmembers. Every design has it's advantages/disadvantages but he has some serious space issues that will make his design difficult.

According to the web that plate is a gusset, I only thought of those in bridges and trusses for houses personally, I usually call them side plates also. The side plates need to be made with tight tolerances so there is less play but he can check for square as he tightens the bolts. My setup seems very solid but it is made with laser cut holes so it has less slop. Right now I think he's on his 5th design and it has a half welded design.▪█─────█▪ Ivanko Barbell Crew #76 ▪█─────█▪

-

10-20-2014, 09:41 AM #83

Thanks for all your responses. A few answers from my side.

I'm thinking that I'll keep both the gusset plates and the bottom welds. Together IMO they will all but eliminate front to back and side sway.

Regarding the concern raised by @GarageIron that the rack will be sitting on the hardware, what I've planned is that the bolts will be inserted from the bottom and tightened by the nut on top. That means that the rack now has exactly eight bolt heads on it's bottom. Seeing that all the bolt heads are of the same dimension, the rack remains level. Does this cause any issues with stability? I could stick some rubber feet to cover the bolt heads. I also remember my fabricator suggesting putting the bolts in countersunk holes to which I expressed skepticism as I fail to comprehend how countersunk holes will be drilled given the 3mm thickness of the steel tube.

@Keetman - Thanks to GarageIron's suggestion I've now lost the plate storage which I think gives me ample room to OHP outside the rack. Besides now the front posts go all the way to the top.

What is still bothering me is how much to extend the base. In other words deciding the footprint of the rack. I'm worried that the rack might topple when I do weighted pull ups. Putting the pull up bar nearer to the rack center seems to be an option but I gotta make sure.

-

10-20-2014, 10:16 AM #84

Ok, if you're going to press on the outside this makes sense. If you were staying inside and you already had overhead issues, it didn't seem like you could make the rack high enough to OH press inside. Just be careful OH pressing on the outside, I'd do it if I couldn't press inside my cage, but it does leave you a little vulnerable.

Can you bolt the cage to the floor or wall? I know you've wanted to make it somewhat easy take down.... but I thought I'd ask. I have to be honest, you've went through so many changes I'm a little lost on all of your parameters. If you can't bolt it, that's fine...but with your space requirements, if it were me, I'd make the rack as shallow as was usable and bolt it for stability. Then you'd have more free area around the cage, a very stable cage, and a place to safely do your work.▪█─────█▪ Equipment Crew #4 ▪█─────█▪

Ivanko Crew #9

York Barbell Crew #13

-

-

10-20-2014, 10:37 AM #85

Well I can't drill holes in the floor if that's what you mean. I have however thought about the possibility of bolting it to layers of plywood that were prefabricated into some crude lifting platform. But then again I'd like it to be stable on its own i.e. without bolting it down.

Regarding the OHP vulnerability thing, I could weld two washers to the end of the safeties instead of the one shown and then that could serve as a backup J-hook. What say?

-

10-20-2014, 11:15 AM #86

As far as the stability goes.... you're just going to have to figure out what best suits your restrictions and needs. You know what you have to work with as far as location, you determine what you need for your workouts, and physics will determine what works for your cage.

I'm not sure I get what you mean on your idea for outside the cage OH pressing. First of all, don't over think it... I wouldn't squat or bench press outside of the cage, but if I had to pick a move to do outside it would be the OH press. All I meant with vulnerability is that on the outside you won't have a safety....safeties are on the inside. Its less likely that you'll crush yourself if you fail, but you could have a complete failure and drop the bar on your head... however, even in a cage that is a possibility. I would just make a second set of jhooks anyway, but I would do that regardless of what I was planning to do on the outside. A second set of jhooks just gives your more flexibility with both sets of uprights on your cage and allows you to eliminate a tiny little bit of setup time (you can have jhooks established for 2 exercises).

Jhooks are not safeties..... JHOOKS ARE NOT SAFETIES. I wasn't sure where you were going with that so I thought I'd make it real clear. Jhooks hold the bar when you aren't there or when you're tired, but they are not safeties. Yes, you can put a second set down low and hope you can slam the bar against them in a failure (before you lose control or before you get below them).... but your mother could also show up just as you're failing so she could spot you. Jhooks are not safeties.

Anyway, I'd just make 2 sets of jhooks for general purpose and when you OH press just turn one set around to the front. You could also design some half rack attachments for the front of your cage for the purpose of giving you more overall flexibility and providing some safety when OH pressing. However, this adds another dimension to the whole stability issue because you'd then have weight on the front of the cage wanting to pull it over on top of you. You'll have to address this if you take may suggestion.▪█─────█▪ Equipment Crew #4 ▪█─────█▪

Ivanko Crew #9

York Barbell Crew #13

-

10-20-2014, 12:01 PM #87

-

10-20-2014, 05:36 PM #88

Dude, that sounds horrible.

Weld some feet on or something...

1) It will allow clearance for the heads of the bolts.

2) It looks better than just leaving the ends of the tube open.

3) It will be easier to get level that way.

I know this method has been criticised as lazy by people in the know on this board, but maybe you could just weld a piece of angle iron to finish the ends?

Like this

-

-

10-21-2014, 01:14 AM #89

The most important aspect of any design is: who is going to build it?, what tools does he has?. level of craftsmanship of the labour?....

Most designs look good on paper. Making the stuff; is another matter.

The problem with holes, bolts, joints, etc, is:

I am making a wild guess, here...

When you use an affordable local manufacturer/welder/builder, he will have cool tools, mig, tig, welder, a nice bench drill, but he surely wont have access to an automatic welding machine (robot) or a laser cutter for the holes.

Ergo, during the manual welding process the metal will be overheated (minimally) and the metal will bend slightly a couple millimeters. Drilling wont be perfect, all the holes will have a slightly different diameter, they wont be perfectly aligned, etc...

Every step in the building process has an error associated; And if your design has to many steps, well, you are exposing yourself to potencial issues that could be avoided...

The easiest way to build that thing; will be.

Full cage or sumo style.

* 2 Vertical panels; All welded.

* 3 Transversal Beams with union bolts to the vertical panels.

Why?

* The bolts on that direction have more room to allow mistakes.

* They can move up and down almost freely by slighly enlarging the connexion holes.

* Each of the 3 beams can be set independently. (adjusted).

That is key; with other designs; you will have to adjust every joint, all together, or in pairs, or in sets defined by plane of placement, to avoid misalignment of the joint bolts and safeties bars. And it is not so fun as it sounds.

The front and rear post; that conform the welded vertical panels; must be presented prior to welding; i mean align the safety holes, you can use some cheap circular wood the same diameter as the safeties. Once it is presented, and perfectly aligned, you can weld.

Otherwise; if the design is to complicated; success is subjected to the craftsmanship and expertice of the labour, and that it is always a bad gamble.

-

10-21-2014, 08:52 AM #90

@Keetman - I get your point. I can't afford to put half rack attachments as I just don't have that kind of space. Space constraint is why I removed the plate holders in the first place. And besides in an OHP scenario the worst (besides crushing my head) that can happen is I let go of the bar and it falls done in front of me. But as Seatard pointed out I might be able to do OHPs inside the rack after all.

@vic - If your see my latest design above, I am building a full cage. I get your concern and thanks for reminding me. One can never be too sure.

@deiphid - I'll probably build some feet. But I still don't see why encasing the bolt heads in rubber won't work. In fact if all the feet are not fabricated in alignment with each other, the rack will be misaligned but the bolt heads are always of the same dimension. Just sayin'.

Similar Threads

-

Cheaps build thread (SS)

By Cheap5.0 in forum Workout JournalsReplies: 175Last Post: 01-03-2011, 05:41 AM -

Check out my home made squat rack

By Cowlifter in forum Workout EquipmentReplies: 20Last Post: 11-06-2007, 02:25 AM -

Help with power rack design

By paulspencer in forum ExercisesReplies: 12Last Post: 02-14-2006, 08:38 PM

Bookmarks